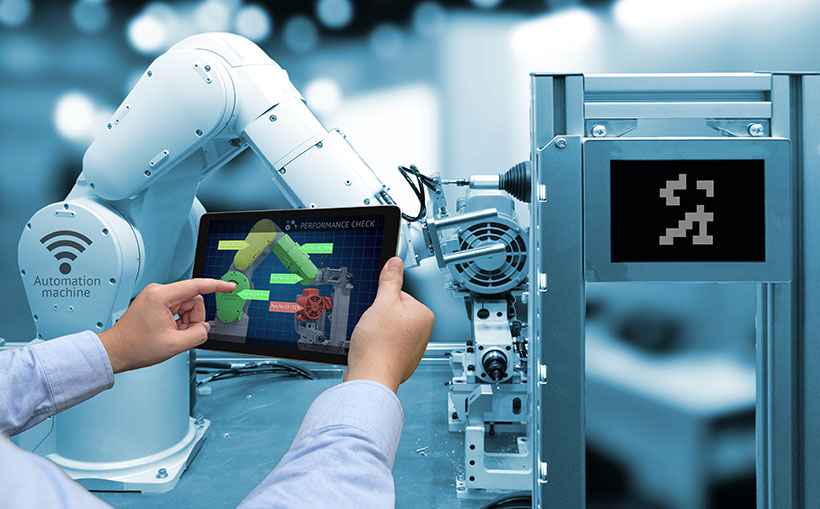

Industry 4.0 is a set of many solutions aligning your processes, machines, people and IT in order to improve the efficiency of your process, lower cycle times and improve your customers’ satisfaction

Better usage of available solutions without major investments

Process Digitization

- Analysis of entire production and supply chain process aiming to identify inefficient activities

- Recommendation to remove or streamline the process – primarily through automation

- Implementation of recommendations and achieving the cost reduction

Project Management

- The planning and forecasting

- Defining new processes

- Training and coaching of employees, suppliers; communication

- Status tracking and reporting, change management

Technology solutions

- We aim to maximize using your existing solutions (e.g. ERP)

- Software – connecting individual IT solutions without need for offline data transfer

- Hardware – sensors, automated logistics systems, readers, mobile work stations etc.

Industry 4.0

-

Production equipment, vehicles, warehouse equipment

-

ERP, specialized software, portable devices, data analytics

-

Sensors, RFID, barcodes

-

Automatize repeated processes, remove waste

Digitization

Paradox of digitization – your ERP is probably already now capable to automatize many processes. Due to fear ofg poor master data you however prefer to conduct the processes manually. Let computers do the routine and direct your people towards problem solving.

-

Automated document creation – e.g. delivery notes, invoices, etiquette’s

-

Automated processes – e.g. stock-out, ordering, production orders

-

Connecting separate internal systems or connecting with 3rd parties via EDI

-

Eliminate printing or manual entry of data, that is already available in some system within your company